Author Affiliations

Abstract

1 Key Laboratory of Materials for High Power Laser, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai201800, China

2 Center of Materials Science and Optoelectronics Engineering, University of Chinese Academy of Sciences, Beijing100049, China

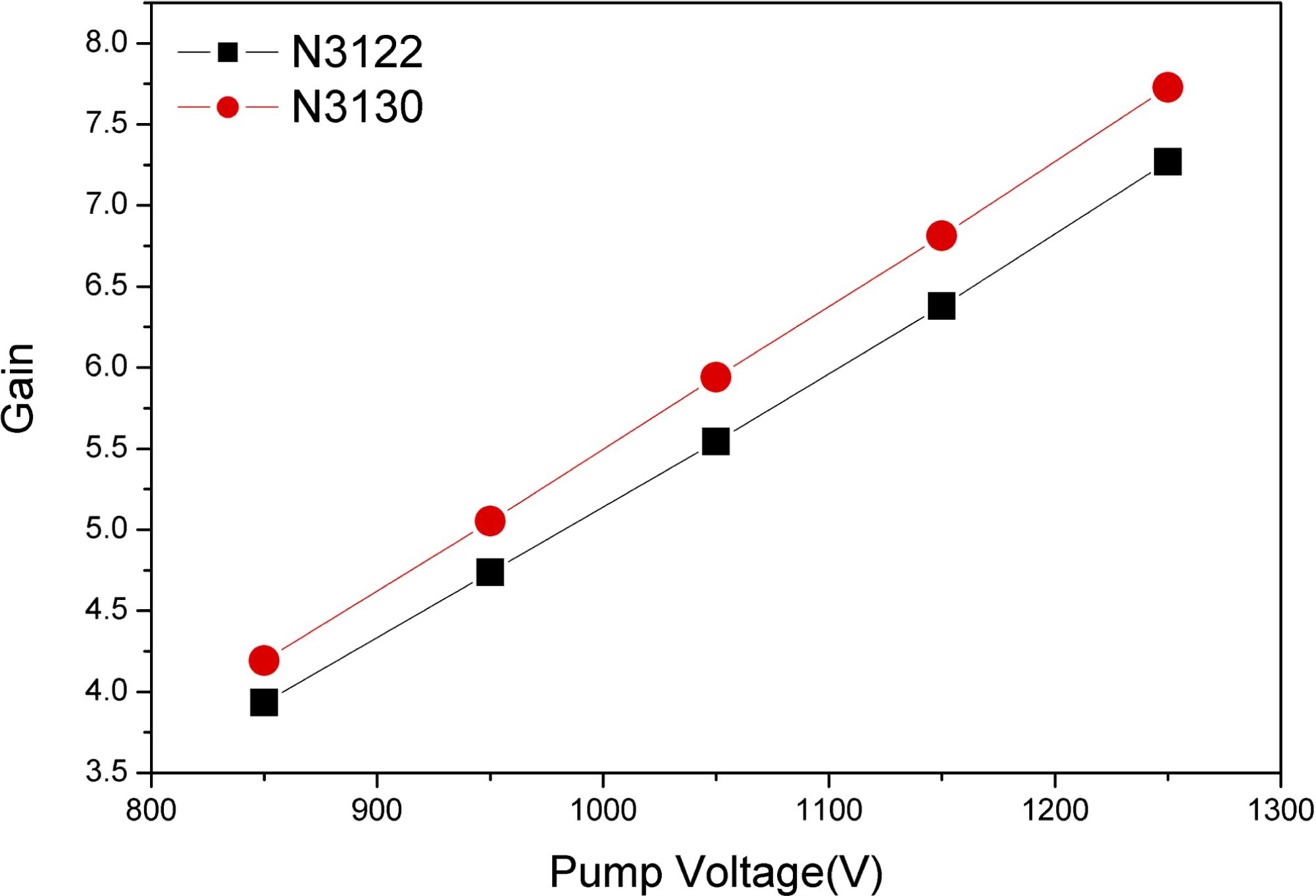

This paper investigates the monolithic edge-cladding process for the elliptical disk of N31-type Nd-doped phosphate laser glass, which will be utilized under liquid cooling conditions for high-power laser systems. The thermal stress, interface bubbles and residual reflectivity, which are due to high-temperature casting and bonding during the monolithic edge-cladding process, are simulated and determined. The applied mould is optimized to a rectangular cavity mould, and the casting temperature is optimized to 1000°C. The resulting lower bubble density makes the mean residual reflectivity as low as 6.75 × 10-5, which is enough to suppress the amplified spontaneous emission generated in the Nd-glass disk, and the resulting maximum optical retardation is converged to 10.2–13.3 nm/cm, which is a favourable base for fine annealing to achieve the stress specification of less than or equal to 5 nm/cm. After fine annealing at the optimized 520°C, the maximum optical retardation is as low as 4.8 nm/cm, and the minimum transmitted wavefront peak-to-valley value is 0.222 wavelength (632.8 nm). An N31 elliptical disk with the size of 194 mm × 102 mm × 40 mm can be successfully cladded by the optimized monolithic edge-cladding process, whose edge-cladded disk with the size of 200 mm × 108 mm × 40 mm can achieve laser gain one-third higher than that of an N21-type disk of the same size.

interface bubble monolithic edge-cladding process N31-type Nd-doped phosphate laser glass residual reflectivity stress birefringence High Power Laser Science and Engineering

2022, 10(2): 02000e14

1 中国科学院上海光学精密机械研究所强激光材料重点实验室, 上海 201800

2 中国科学院大学, 北京 100049

硬包边是激光钕玻璃减少放大自发辐射和抑制寄生振荡的包边技术之一,残余应力是硬包边的一个重要参数。详细描述了激光钕玻璃硬包边过程中残余应力的来源,并利用有限元分析软件COMSOL Multiphysics,对硬包边浇注熔接过程中不同膨胀系数匹配条件和不同包边玻璃浇注温度下的残余应力分布进行了数值模拟。结果显示,激光钕玻璃和包边玻璃的膨胀系数差异愈小,产生的残余应力愈小;包边玻璃浇注温度愈高,则产生的残余应力愈大。硬包边实验结果表明:包边玻璃的膨胀系数和激光钕玻璃的膨胀系数愈相近,则残余应力就愈小,当包边温度在700~1200 ℃范围内时,残余应力随着包边温度的增加而增大。模拟结果与实验结果吻合,所以在硬包边的浇注熔接过程中,为了使残余应力最小,最佳策略是激光钕玻璃的膨胀系数和包边玻璃的膨胀系数尽量接近甚至相等,且包边温度尽量低。

材料 激光钕玻璃 硬包边 有限元分析 激光元件 应力双折射率 残余应力

Author Affiliations

Abstract

Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai 201800, China

A novel four light ray path test method for measuring residual reflectance has been presented. Residual reflectance spatial distribution at a cladding interface was measured using the technique. Residual reflectance could be on the order of 10?5 by matching the refractive index of Nd:glass, polymer, and cladding glass and eliminating defects in the adhesive layer. Residual reflection spatial distribution appears to be similar to Newton rings due to the edge surface flatness. The relationship between the residual reflectance and the edge surface flatness was discussed, and the results revealed that the edge surface flatness is very important during the cladding process.

residual reflectance edge cladding Nd:glass amplifier Chinese Optics Letters

2020, 18(9): 091402

中国科学院上海光学精密机械研究所激光玻璃研发中心, 上海 201800

报道了磷酸盐激光钕玻璃的连续熔炼线,以及采用连续熔炼工艺获得的400 mm 口径N31 钕玻璃的主要性能。连熔所制备的N31-35 钕玻璃的掺杂离子浓度为3.47(±0.02)×1020 cm-3;1053 nm 处的折射率为1.5336±0.0005;400 nm 处的吸收系数平均值为0.098 cm-1;1053 nm 处的激光波长损耗为0.13~0.15% cm-1;3000 cm-1 处的吸收系数平均值为0.83 cm-1。400 mm 口径连熔N31 钕玻璃的透射波前畸变在633 nm 处小于λ/3 波长。采用1053 nm、脉冲为3 ns激光作用下连熔钕玻璃的体破坏阈值大于40 J/cm2。结果表明,在N31 钕玻璃的连续熔炼工艺中,除铂金和除水都取得了很好的效果。

光学制造 激光钕玻璃 连续熔炼工艺 损耗 增益系数

1 中国科学院上海光学精密机械研究所, 上海 201800

2 中国科学院大学, 北京 100049

为减少放大自发辐射和抑制寄生震荡,需在激光钕玻璃片侧面粘接一层吸收介质包边玻璃,其中,包边残余应力是粘接的一个重要参数。详细描述了激光钕玻璃与包边玻璃在包边粘接过程中粘接界面附近残余应力的来源,实验讨论分析了精密退火、加工、包边粘接等对界面附近残余应力的影响。结果表明,退火过程中的边缘应力对粘接界面附近残余应力影响比较大,且包边面加工面型匹配越差,则界面附近残余应力越大,而低收缩率和低模量的粘接胶对界面附近的残余应力影响较小。

激光技术 激光钕玻璃 包边 残余应力 应力双折射

Author Affiliations

Abstract

Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai 201800, China

Large aperture Nd:phosphate laser glass is a key optical element for an inertial confinement fusion (ICF) facility. N31, one type of neodymium doped phosphate glasses, was developed for high peak power laser facility applications in China. The composition and main properties of N31 glass are given, together with those of LHG-8, LG-770, and KGSS- 0180 Nd:phosphate laser glasses, from Hoya and Schott, and from Russia. The technologies of pot melting, continuous melting, and edge cladding of large size N31 phosphate laser glass are briefly described. The small signal gain profiles of N31 glass slabs from both pot melting and continuous melting at various values of the pumping energy of the xenon lamp are presented. N31 glass is characterized by a stimulated emission cross section of 3:8 � 10??20 cm2 at 1053 nm, an absorption coefficient of 0.10–0.15% cm??1 at laser wavelength, small residual stress around the interface between the cladding glass and the laser glass, optical homogeneity of �2 � 10??6 in a 400 mm aperture, and laser damage threshold larger than 42 J/cm2 for a 3 ns pulse width at 1064 nm wavelength.

neodymium phosphate laser glass large aperture glass ICF facility High Power Laser Science and Engineering

2014, 2(1): 010000e1

Author Affiliations

Abstract

1 Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai 201800, China

2 University of Chinese Academy of Sciences, Beijing 100049, China

An Nd:glass disc requires an edge cladding to absorb the amplified spontaneous emission. The absorption is determined by reflections (R) from disc edges. R is primarily induced by the refractive index (n) mismatch. Thus, the temperature at the cladding interface increases due to absorption, and leads to the variation of n. In order to investigate the effect of temperature on the refractive index match, temperature coefficients (dn/dT) of the laser glass, adhesive polymer, and cladding glass are measured. The effect of temperature on the refractive index match is discussed. Results show that the indices match below 40°C.

140.3530 Lasers, neodymium 120.6780 Temperature 230.5480 Prisms Chinese Optics Letters

2014, 12(10): 101401

Author Affiliations

Abstract

Nd-doped phosphate glass is the dominant amplifier material used in solid state high average power laser systems. Surface imperfection and subsurface damage (SSD) of the glass, resulting from the optical fabrication process, limit the increment of laser system energy output. Thus, it is important to enhance the surface damage threshold of Nd-doped phosphate glass surface. The in°uence of abrasive size, polishing powder, grinding mode, and chemical treatment on the laser-induced damage threshold (LIDT) of Nd-doped phosphate glass surface is investigated. Results show that the LIDT is affected little by different polishing powders and grinding modes. The LIDT correlates with the abrasive size, which produced different depths of SSD. A suitable acid etching treatment can remove the imperfection and the SSD for improving the LIDT of Nd-doped phosphate glass surface. The combination of several effective techniques and methods, which are low-cost and practical, should be useful to enhance the LIDT of Nd-doped phosphate glass surface.

140.3330 Laser damage 140.3530 Lasers, neodymium 240.6700 Surfaces Chinese Optics Letters

2012, 10(4): 041403

中国科学院 上海光学精密机械研究所, 上海 201800

在概述国内外高功率激光钕玻璃的发展及其主要性质的基础上,重点论述了上海光学精密机械研究所在大口径N31高功率激光钕玻璃半连续熔炼工艺、连续熔炼工艺、包边工艺等方面的研究进展。报道了半连续熔炼工艺制备的不同Nd2O3浓度N31钕玻璃的光吸收损耗和荧光寿命及小信号增益系数,并给出了这些钕玻璃坯片小信号增益系数的波动范围。通过对半连续熔炼和连续熔炼工艺制备的N31激光钕玻璃主要性能的比较,证明连续熔炼工艺制备的N31钕玻璃的主要性能指标与半连续熔炼的性能相当。对于400 mm大口径N31钕玻璃坯片的包边进行了模拟考核,结果表明,采用现有包边工艺的钕玻璃可以承受1 000次高功率氙灯辐射。

高功率激光 钕玻璃 大口径 惯性约束聚变 high power laser neodymium laser glass large aperture inertial confinement fusion 强激光与粒子束

2011, 23(10): 2560

Author Affiliations

Abstract

Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai 201800

Experimental investigation was performed with a 1064-nm, 10-ns Nd:YAG laser to determine the effects of the surface hydrogen acid etching on laser damage, compared with damage of conventionally polished surface. The investigation was helpful for us to understand the negative effects of Nd-doped phosphate glass surface and subsurface damage (SSD) on laser induced damage threshold (LIDT). A set of samples was polished, and then chemically etched in a cool buffered 10%HF + 20%H2SO4 solution at different times. Another set of samples was ground and etched in the hot-buffered solution, and then polished. All the samples were irradiated with Nd: YAG laser and characterized by optical microscopy. Results of LIDT were obtained according to International standard ISO/DIS 11254-1.2. Chemical treatment can remove the contaminants in the polished re-deposition layer and the SSD for improving the laser damage resistance of Nd-doped phosphate glass surfaces. The method of using hot solution was more effective than that of using cool solution.

亚表面缺陷 激光损伤 磷酸盐激光玻璃 140.3330 Laser damage 140.3530 Lasers, neodymium 240.6700 Surfaces Chinese Optics Letters

2008, 6(9): 681